H2 Tank Control

What is a H2 Tank Controller

The H2 Aero Tank Controller manages all essential functions of a cryogenic hydrogen tank system under all flight conditions. It controls the refueling valves, monitors the fill level, temperature, and stable tank pressure, and ensures a reliable supply to the fuel cell.

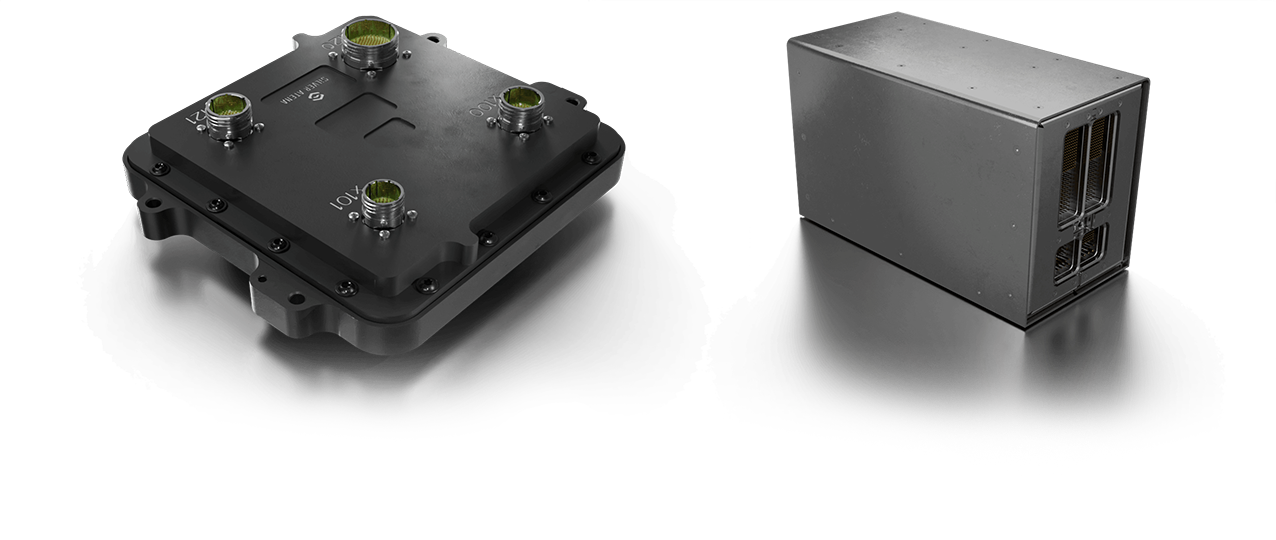

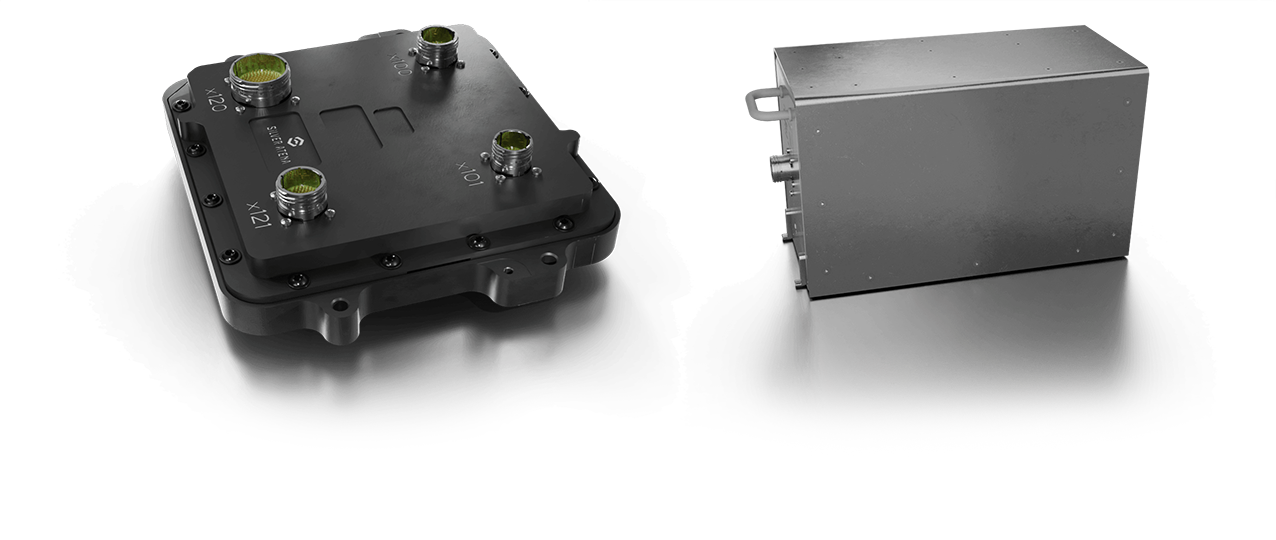

For maximum adaptability, the system is divided into two modules. The Tank Control Unit (TCU) provides the communication interfaces and processing power and controls all outputs, while the Tank Data Acquisition Module (TDAM) reads most sensor interfaces and transmits the data to the TCU via a bus interface. This split architecture offers great flexibility regarding changes to the sensor interfaces.

Features

Highest aviation safety standard through redundant control and monitoring architecture with multiple CPUs.

- Filling: Valve control for inerting* and filling the H₂ tank

- Condition monitoring

- Fill level (tank)

- Pressure (tank and supply lines)

- Temperature (tank and supply lines)

- Vacuum insulation integrity (tank and supply lines)

- Valve position

- H₂ supply: Valve control for supplying gaseous or liquid H₂ to the fuel cell

- Validation of sensor and actuator signals

* = Displacement of oxygen to minimize the risk of unwanted chemical reactions

Applications

- Systems with cryogenic hydrogen tanks

- Fuel cell systems

- Hydrogen combustion systems

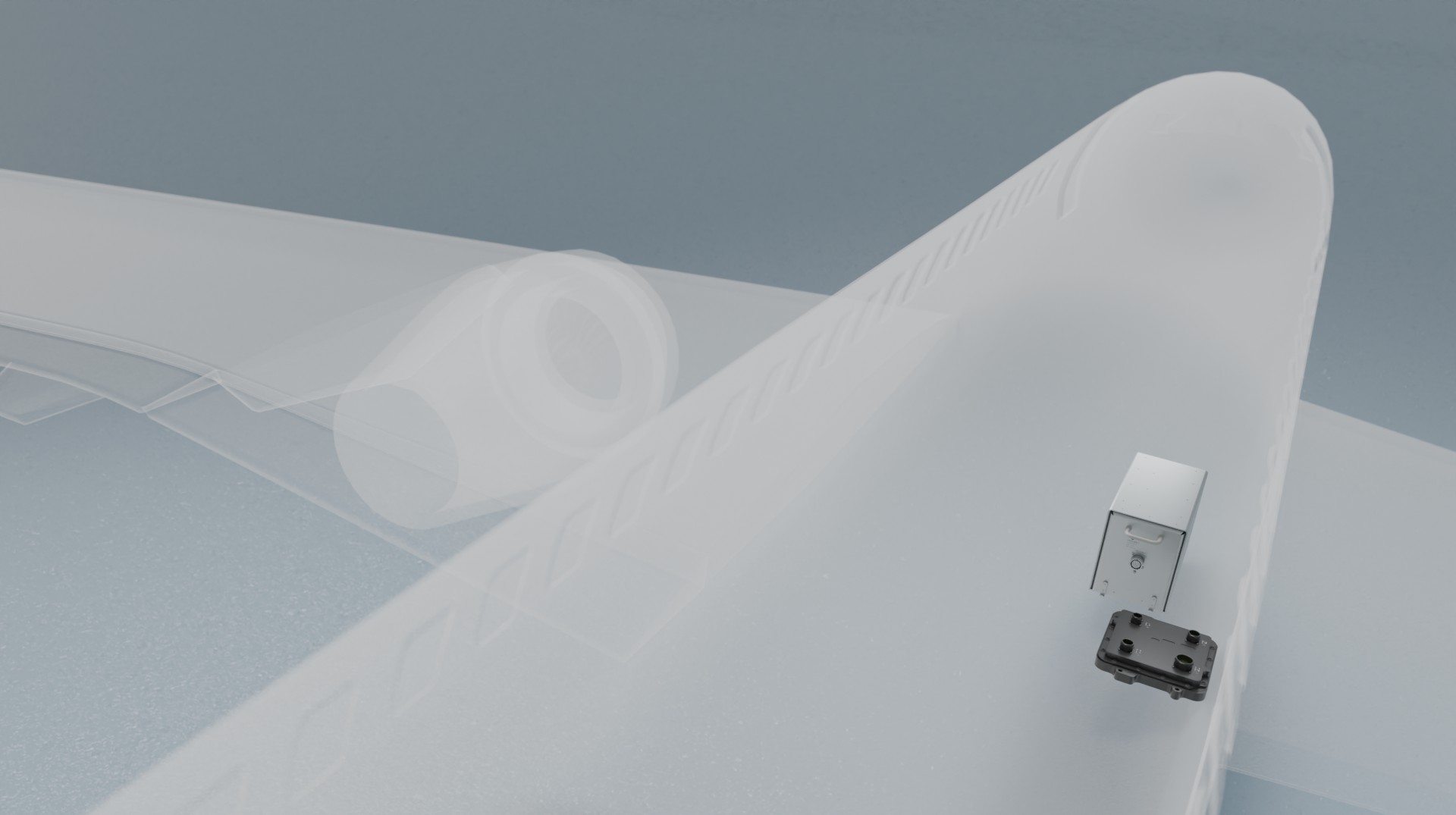

The H2 Tank Control Unit in 3D-View

Please click on the image to activate the 360˚ view.

Specifications

- Input Voltage: Two 28 V buses

- Output Interfaces:

- Solenoid valve interfaces

- Stepper motor interfaces

- Discrete output interfaces

- Input Interfaces:

- Thermodiodes

- Passive capacitive sensors

- Resistive sensors

- 5 V ratiometric sensors

- Discrete input interfaces

- Position sensors

- Resolver interfaces

- Communication Interfaces: ARINC 825 / CAN

- Safety Classification: DAL A monitoring channel and DAL C control channel

Application Areas

- UAVs

- Electric VTOL aircraft

- General aviation aircraft

- Regional jets

Advantages

- Easy adaptation to different conditions – maximum flexibility for various application scenarios.

- High number of sensor and actuator interfaces – ideal for complex systems with many inputs and outputs.

- Developed according to DAL A – meets the highest safety and reliability standards.

- Dissimilar Computing Elements (CPUs) – increased reliability through redundancy and different processing units.

- Controller enables the integration of additional functions – scalable for future requirements.

- High number of communication interfaces – supports a wide range of protocols for seamless system integration.

Why choose this product?

Handling hydrogen presents several safety challenges.

Our many years of experience with hydrogen systems enable us to develop sophisticated and safe tank control units.

Why Silver Atena?

For over 25 years, the company has been a leader in the development of control units and power electronics for safety-critical applications in the automotive, aerospace, and industrial sectors. This includes, in particular, solutions for hydrogen propulsion and fuel cell systems.

This experience is crucial, as hydrogen systems must meet the highest safety standards.