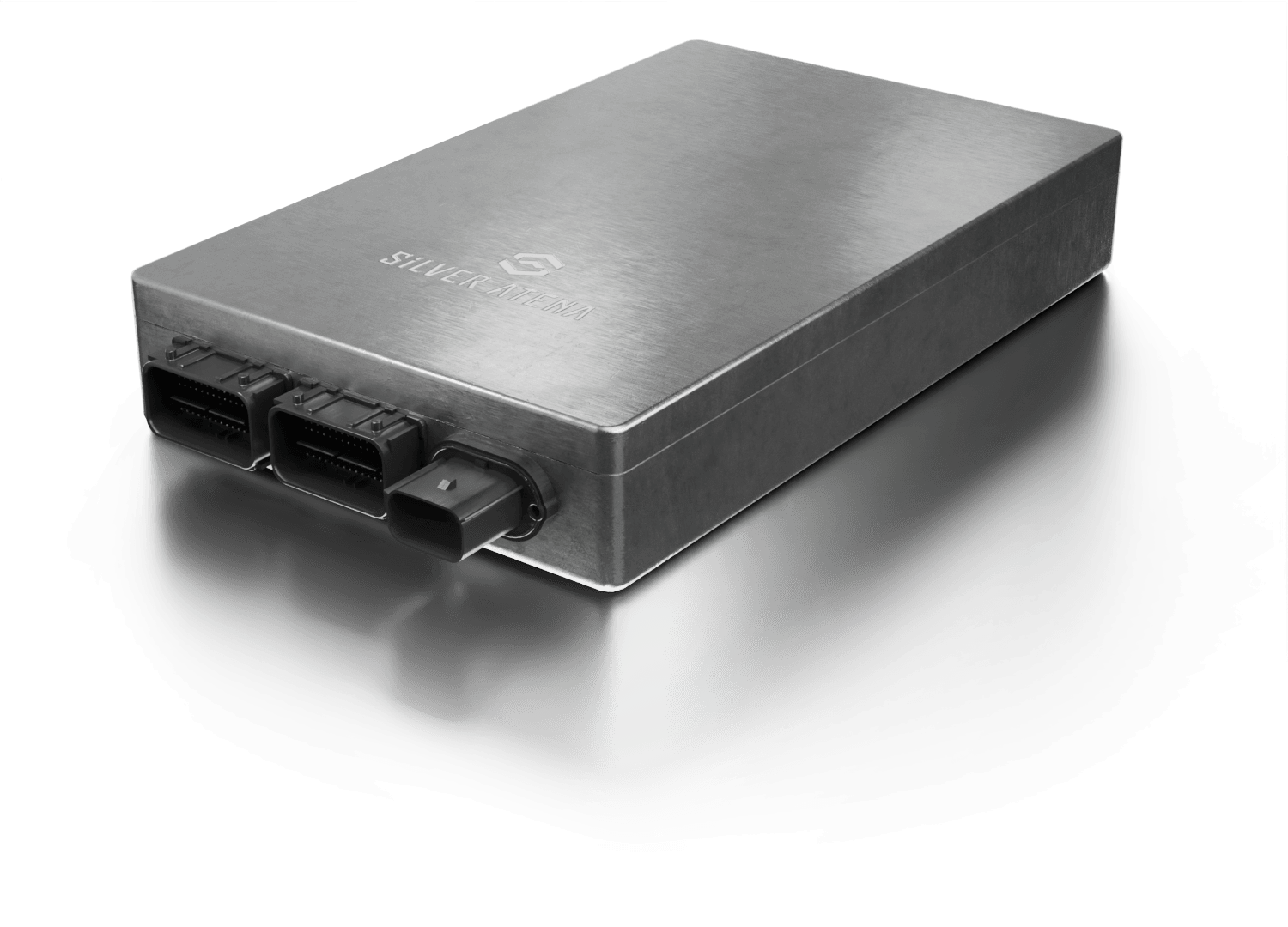

Tank Control Unit

What is a Tank Control Unit?

The hydrogen tank control unit combines precise monitoring and safe control of hydrogen-powered vehicles with cryogenic hydrogen supply.

It regulates and monitors the refueling and hydrogen supply to the engine or fuel cell, supporting safe overall operation.

The hydrogen ECUs perform safety functions such as gas detection and boil-off control, and provide helpful status messages and automated emergency calls, not only in the event of a malfunction.

This H2 control unit, designed for maximum safety and reliability, is a crucial component of modern hydrogen mobility solutions.

Features

- Tank pressure regulation: precise control of LH2 pressure during operation

- Gas concentration monitoring: warnings in the event of leaks or limit violations

- Monitoring of critical tank parameters and response to limit values (pressure, temperature)

- Boil-off management: monitoring of hydrogen loss through diffusion

- Interface to engine control and central control unit

- Monitoring of the LH2 refueling process

- Diagnostics: informing the driver about the system status

- Emergency notification: automatic emergency call activation in the event of critical system errors

Applications

Hydrogen-operated vehicles with either Fuel Cell (electric vehicle) or hydrogen combustion engine.

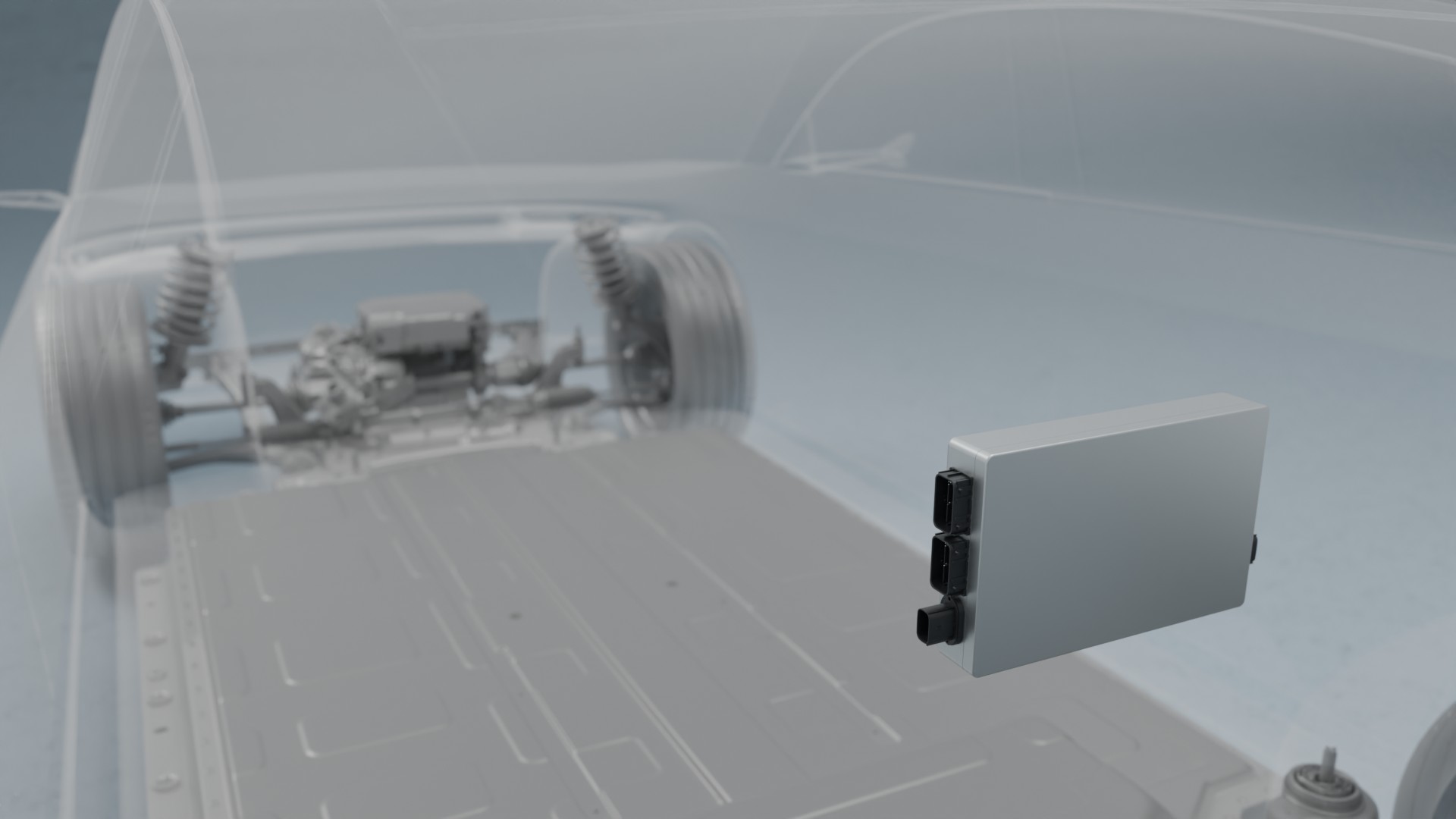

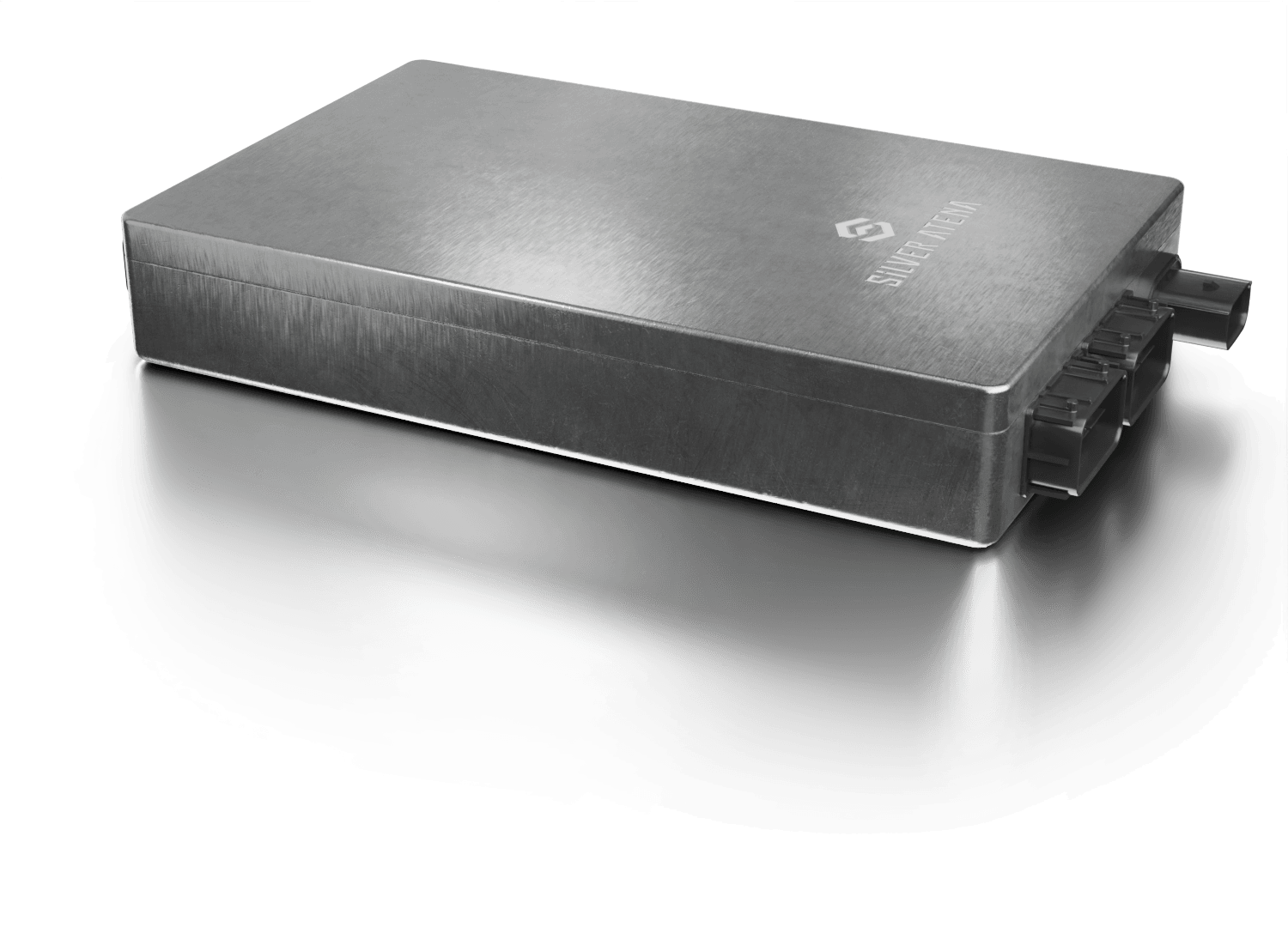

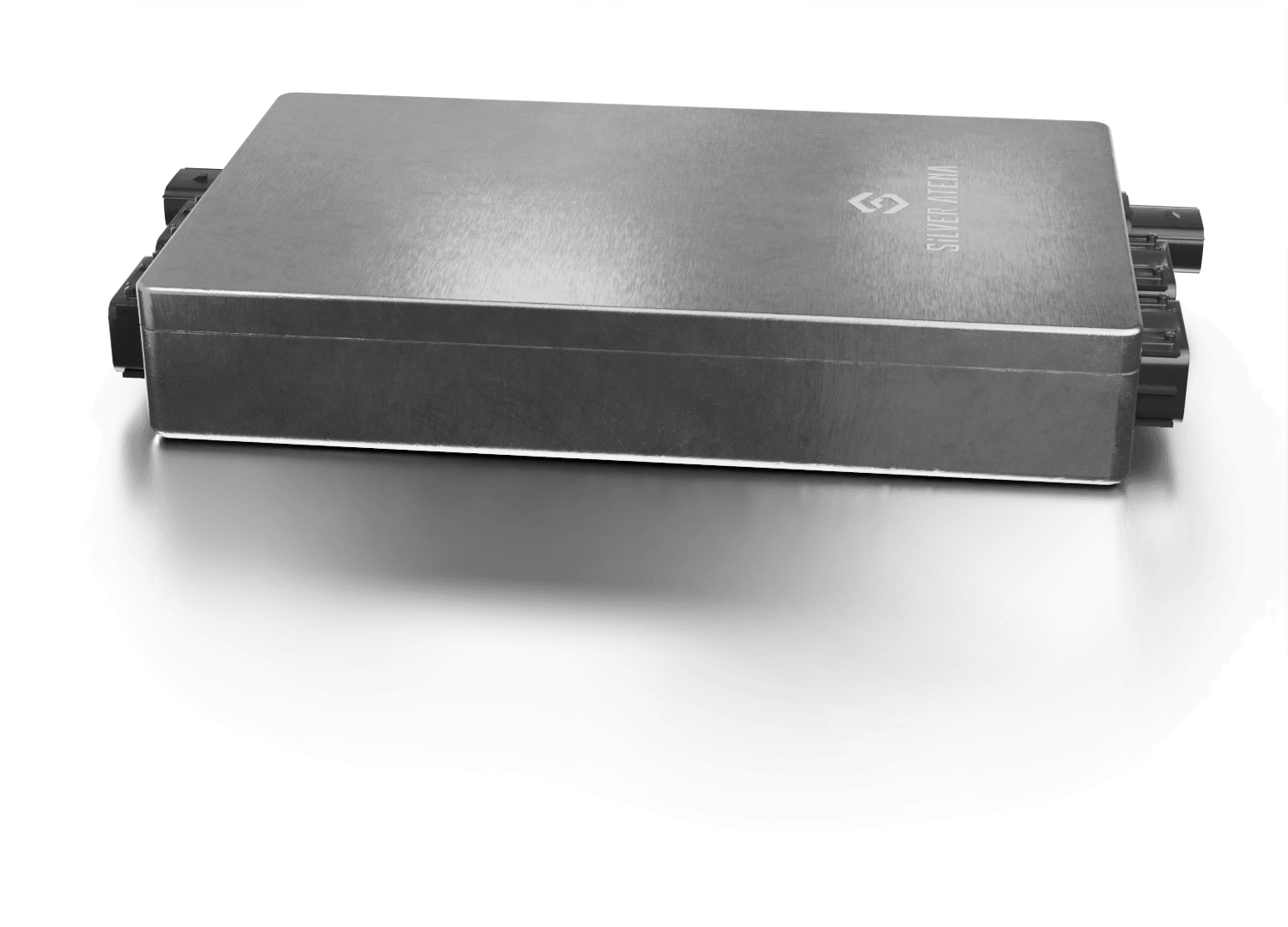

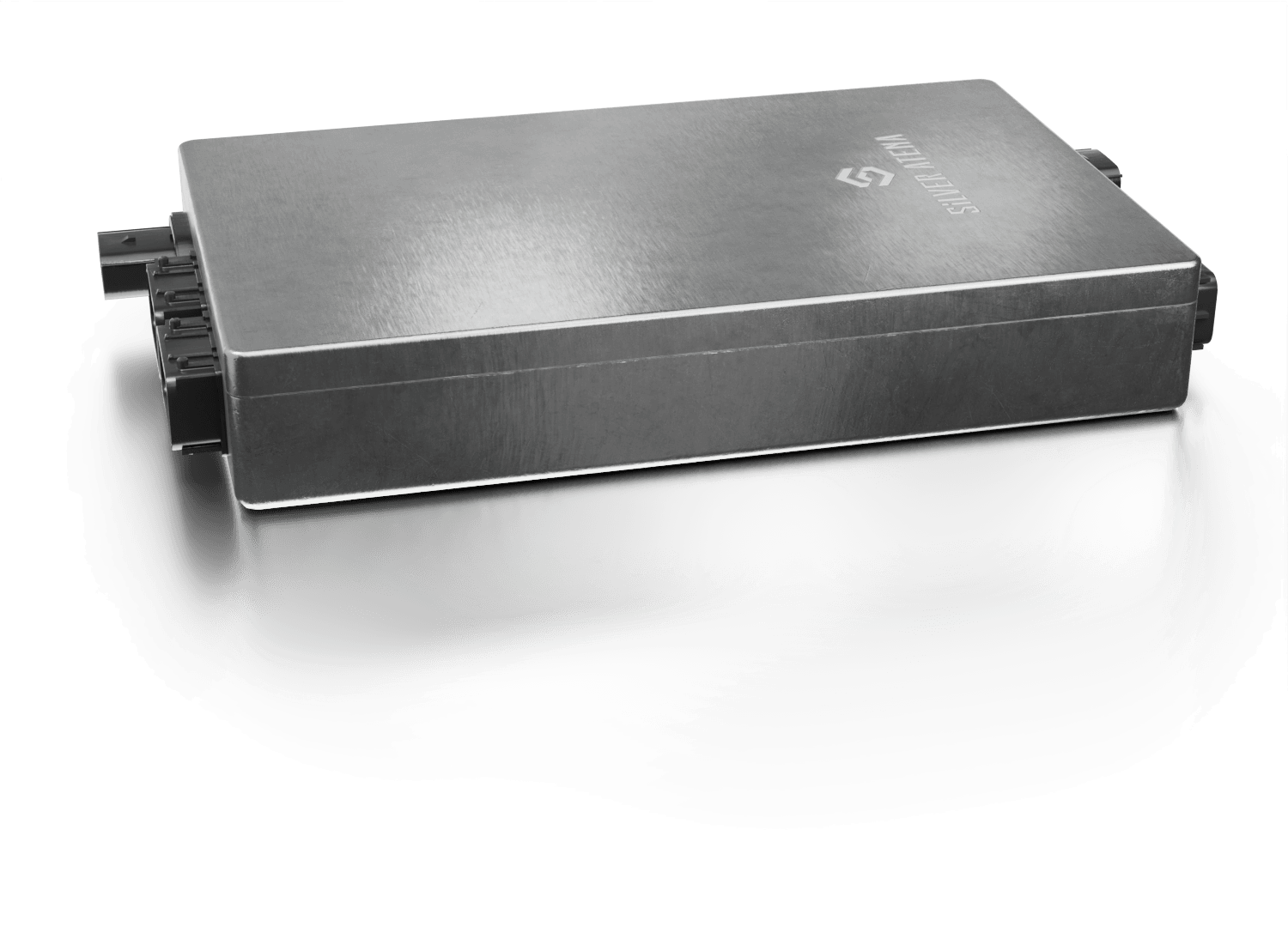

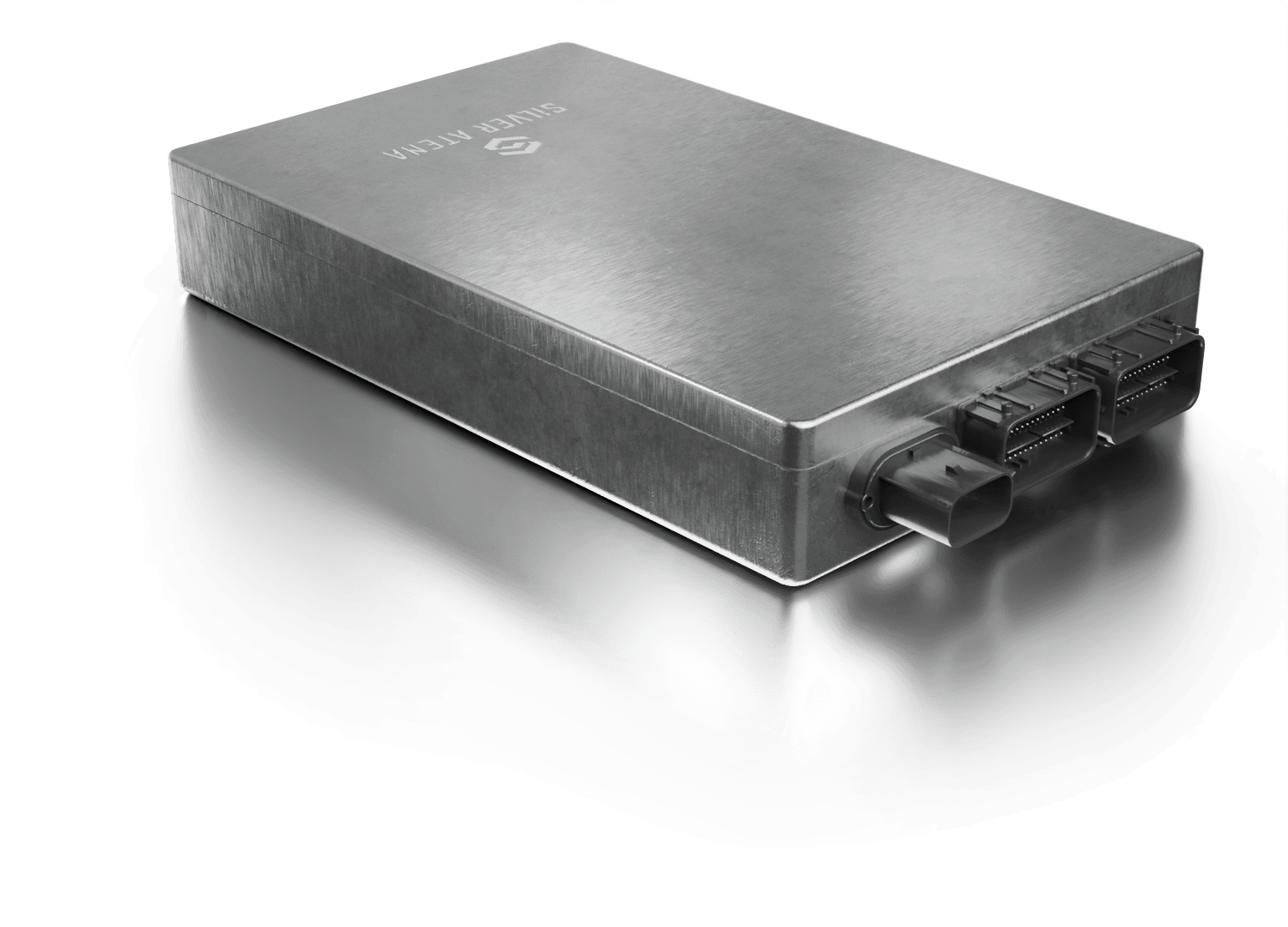

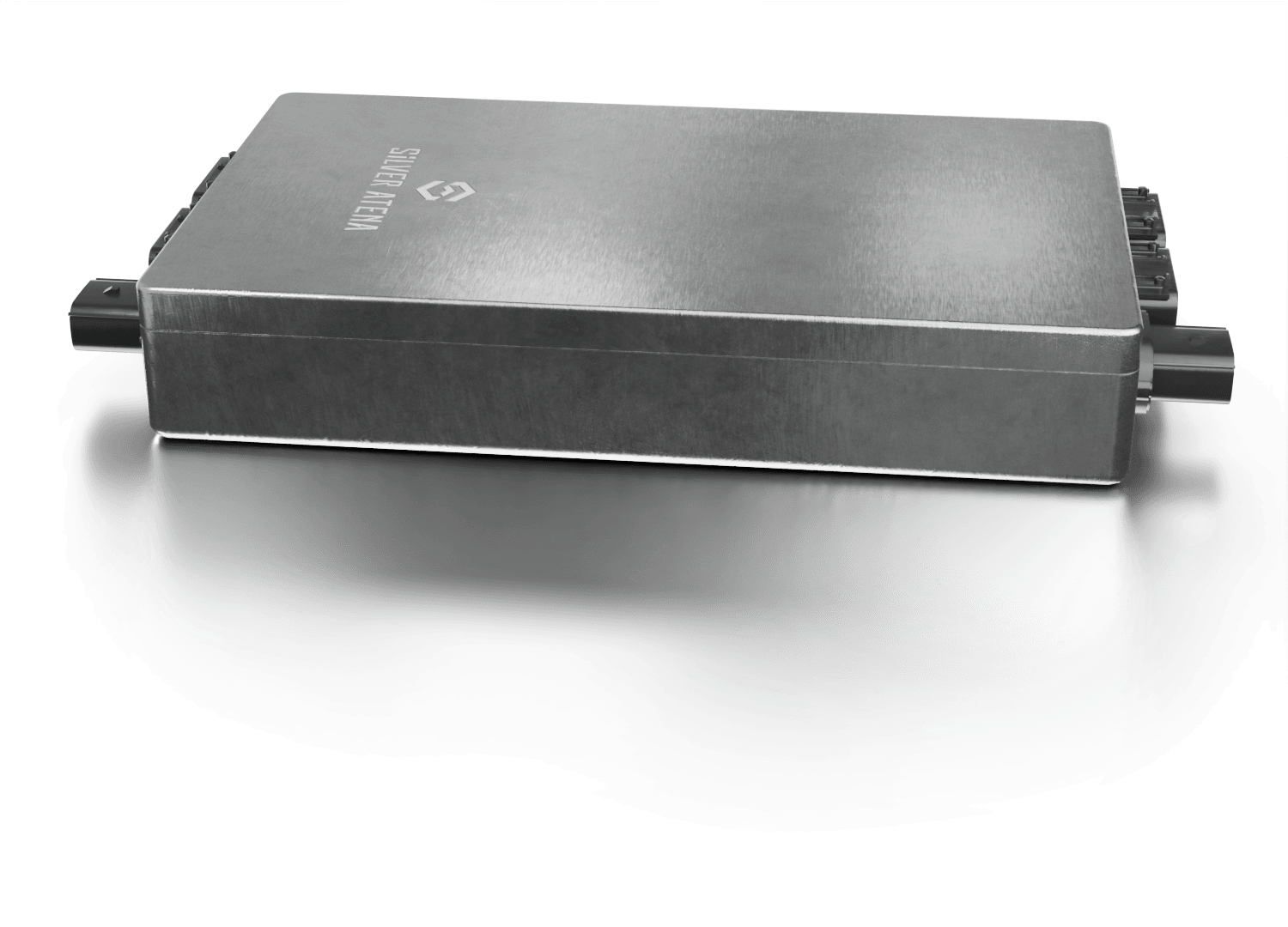

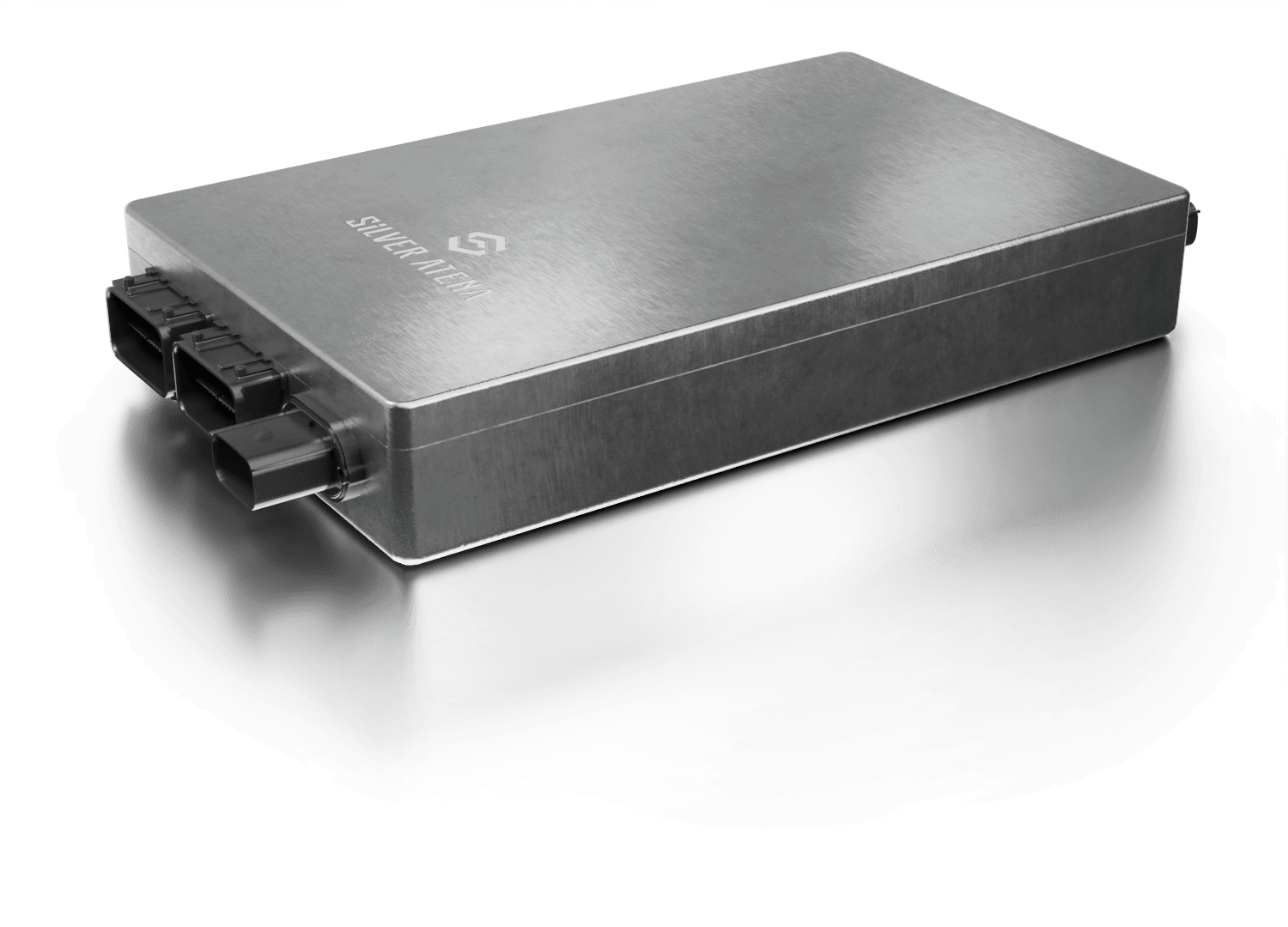

The Tank Control Unit in 3D-View

Please click on the image to activate the 360˚ view.

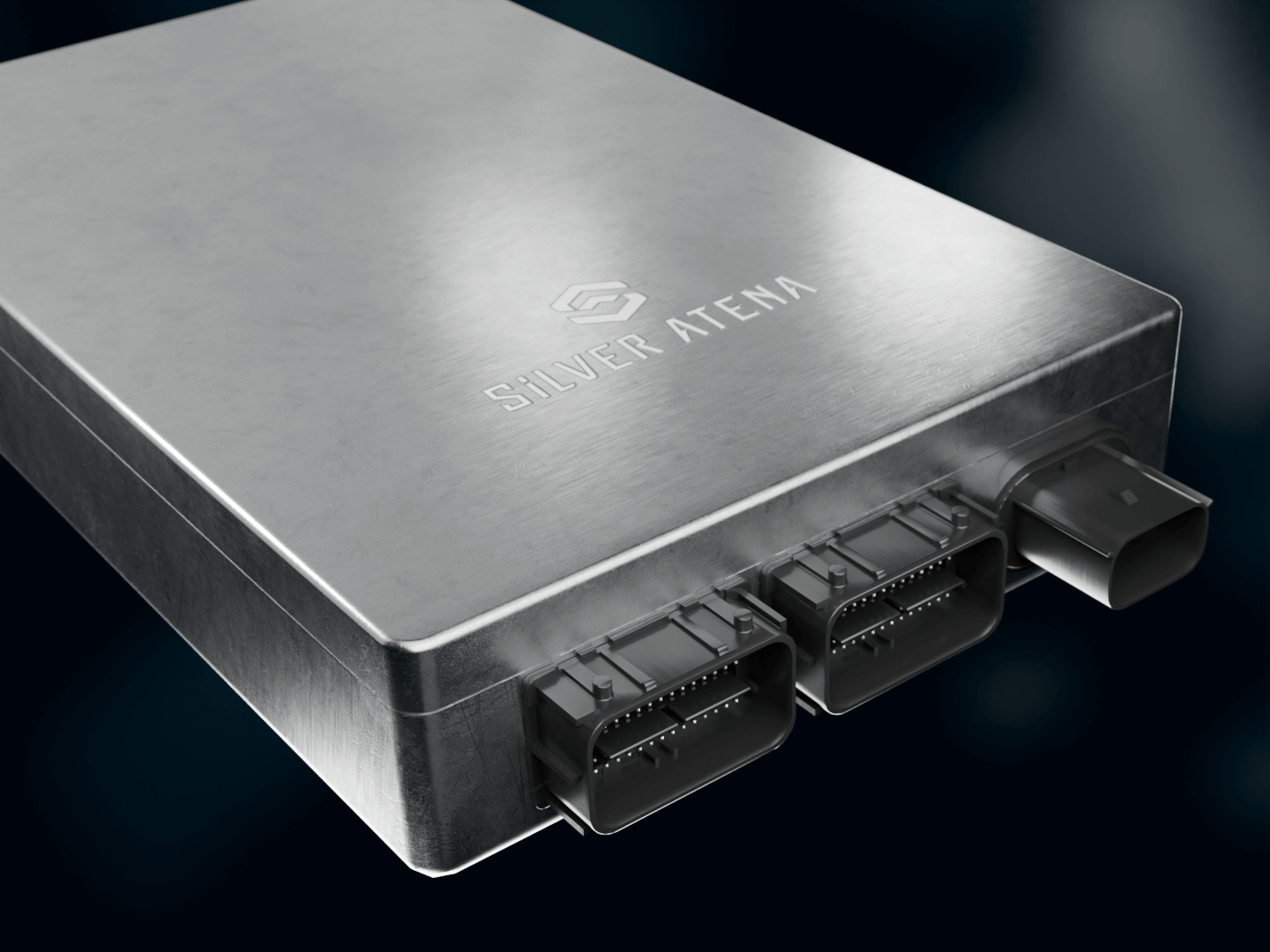

Specifications

- Controls and monitors:

- Refuelling process

- Hydrogen supply to the engine

- Safety functions: gas warning, boil-off function

- Development according to automotive/industrial safety standards (ISO 26262/IEC 61508)

Application Areas

- Fuel cell cars and commercial vehicles

- Hydrogen-powered trucks, buses, and industrial trucks

- Ferries, yachts, and boats powered by hydrogen

- Aircraft, drones

- Stationary energy systems (emergency power supplies, mobile power containers, microgrids)

Advantages

The system is designed for continuous operation under demanding conditions and is characterized by high mechanical and electronic robustness. Safety-relevant functions such as gas detection, automated emergency call, and boil-off management are fully integrated and ensure reliable operation. The architecture is compatible with both fuel cell and hydrogen engine-based drive systems. The control unit supports direct communication with the engine control unit and a central service center, enabling efficient system diagnostics, maintenance, and operational optimization.

Why choose this product?

Silver Atena has been developing field-proven control units for hydrogen applications in various industries for many years. The use of automated code generation significantly reduces development times without compromising quality. The software is certified to meet the highest safety requirements (SIL3), making it ideal for safety-critical applications. This is complemented by many years of project experience working with OEMs and partners in the automotive and aerospace industries, ensuring a deep understanding of complex system requirements.

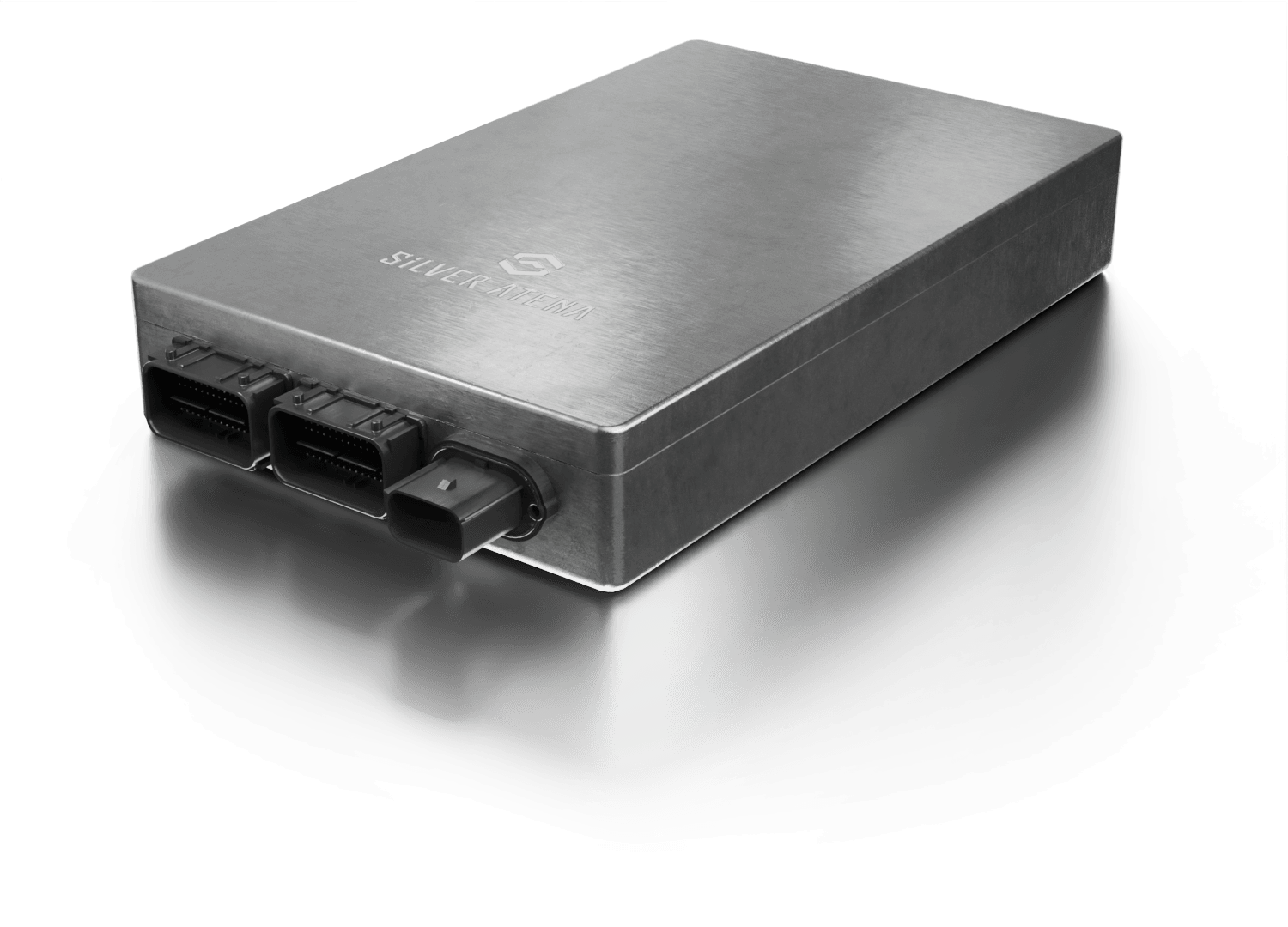

Why Silver Atena?

As experts in safety-critical applications, we are your preferred supplier of products for mobile hydrogen applications.

Our solutions have been successfully integrated into production vehicles for more than 20 years.

Silver Atena was one of the first suppliers in the automotive industry to develop automatic code generation for SIL3 software and implement it for safety-critical applications in a vehicle.