Automotive

High-performance solutions for Automotive

Silver Atena is the driving force behind the electrification of mobility: We develop competitive products – from pre-development and prototypes to SOP and series production. Our focus is on electric motor inverters and DC/DC systems, as well as safety ECUs up to ASIL-D.

These form the basis for high-performance drive technologies, chassis and torque vectoring applications, highly efficient on-board power supply and charging solutions, and intelligent vehicle safety architectures.

Automotive Focus Areas

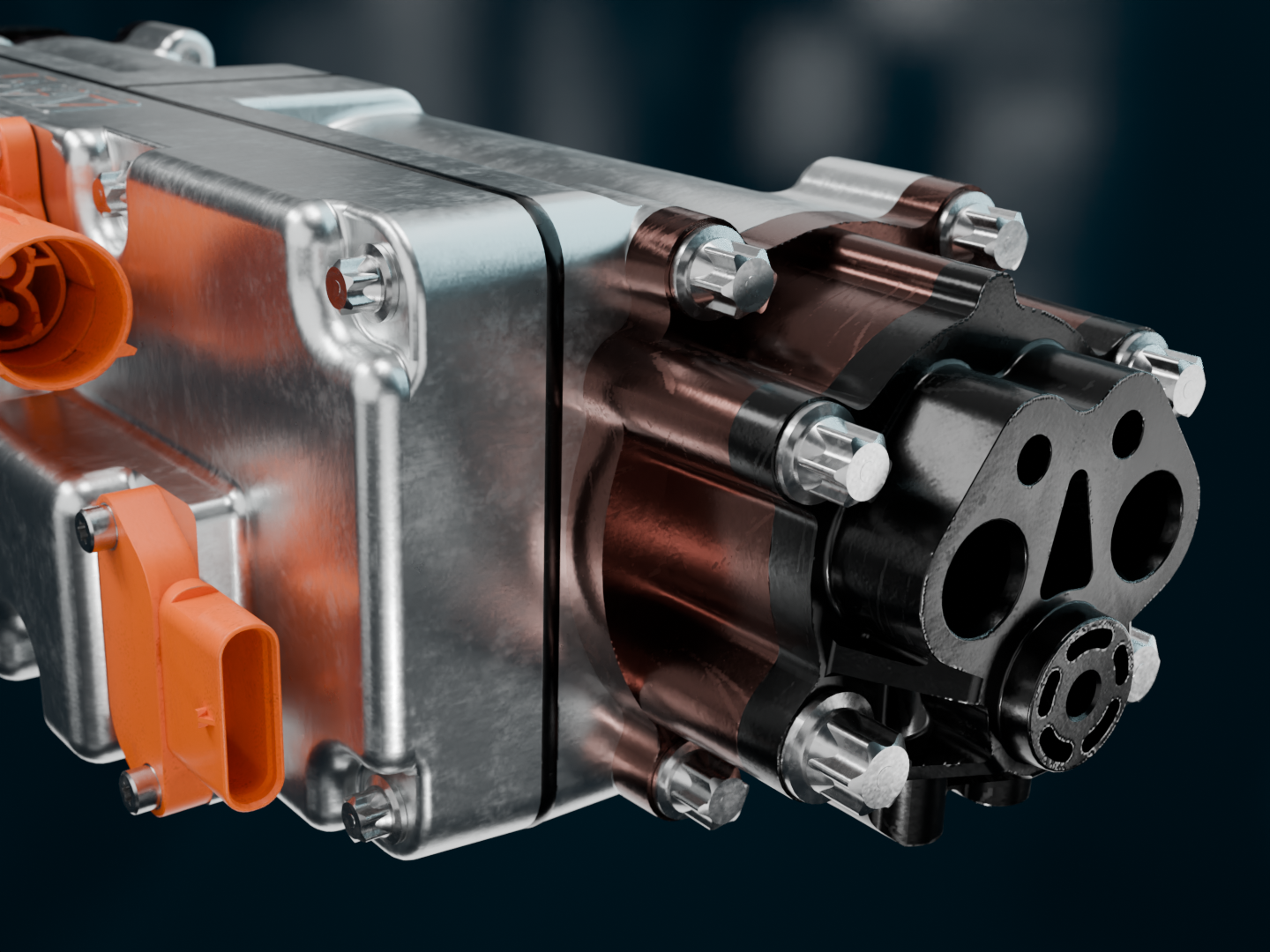

Inverters (High Voltage, High Speed, Powertrain & Electric Motor)

Development of high-voltage inverters – including high-speed applications. From system and controller development to series production.

DC/DC Converter (400 V / 800 V)

DC/DC converters (Si/SiC) for 400 V and 800 V architectures – with series production references in the fuel cell applications.

Safety ECU / Safety Gateway (up to ASIL-D)

Safety-enabled control units and communication gateways for increased system safety and modern vehicle architectures – up to ASIL-D.

Vehicle applications

High-Voltage Inverters for Vehicle Powertrain

Power inverters for electric powertrains, including torque vectoring – compact and reliable for efficient and safe propulsion.

Active Chassis Systems

Highly dynamic suspension systems for premium vehicles – including series production projects (48 V to 800 V).

Charging Technology

Solutions for all your charging needs – e.g., DC boost chargers that allow 800 V vehicles to be charged using 400 V DC chargers.

FuelCell DC-DC Converter

Reliable power supply with stable on-board voltage.

Safety ECUs / Safety Gateways

Safety-enabled control units and communication gateways for enhanced system safety and modern vehicle architectures – up to ASIL-D.

Proven References – Development & Series Production

A selection of successful series production and development projects: from AUTOSAR software development to powertrain, chassis, and safety systems.

Reference Highlights

- Safety Gateway (ASIL-D): Interface between ADAS and the central vehicle gateway, external vehicle access.

- Active Chassis: HV damper control 400/800 V, dual inverter

- SiC Fuel Cell DC/DC: 800 V, 90 kW, Gen 4

- DC Boost Charger: 50 - 75 kW DC/DC, enables 800 V vehicles to operate on 400 VDC

- High-Speed Inverter: up to 160,000 rpm

- 800 V SiC Drive Inverter: 230 kW, synchronization of 2 drives/axle, torque vectoring

Trends & Use Cases in Automotive

- E-Mobility & 800V Platforms

Power electronics and control units for scalable electric drive architectures – from charging boosters to drive inverters - Hydrogen & Fuel Cells

Components and systems for fuel cell architectures – including fuel cell DC/DC converters and control/monitoring. - Active Suspension

Active damping systems for premium vehicles – designed for dynamics, integration, and series production. - Enhanced System Safety

Safety concepts and safety ECUs/gateways for demanding requirements and secure vehicle access.

From System Engineering to Production

We cover the entire product development cycle: system engineering, hardware, software, mechanics, functional safety & security, testing & validation, as well as production and series delivery.

End-to-End Services

- System Engineering & Requirements

- Hardware/Software/Mechanical Design

- Functional Safety & Security

- Test & Validation / Qualification

- Production & Series Support (including obsolescence, complaints/8D)

Series production capability – flexibly scalable

IATF 16949 certified. For large volumes, we collaborate with established manufacturing partners in long-term partnerships and remain flexible should customers require alternative setups or a change of manufacturer.

Series models:

- External via drop shipping: Series delivery up to 250,000+ units/year possible

- In-house assembly: up to 30,000 units/year

Test & Validation: Robust Systems, Reliable Evidence

Our laboratories support the entire development cycle with:

- project/product-specific HiL and EoL test benches

- engine test bench (150 kW load)

- EMC chamber

- climate chambers

- battery/load simulators

for realistic test scenarios.

Added Value for OEMs, Tier 1 and Tier 2 Suppliers

For OEMs

Engineering services for ECUs (from pre-development to after-sales), consulting (safety, security, EMC), prototype production, process implementation, and small/medium production runs including delivery. Benefits: specific expertise, rapid prototyping (time-to-market), and coverage of capacity bottlenecks.

For Tier-1/Tier-2

Support from initial quote preparation to OEM prototype/small production run including delivery and process implementation. Benefits: market segment expansion, transformation support, and improved time-to-market.

Let's talk about your project.

Are you planning a safety-relevant control unit, power electronics, or a mechatronic system?

We provide pragmatic support – from concept to series production.