Electric turbocharger

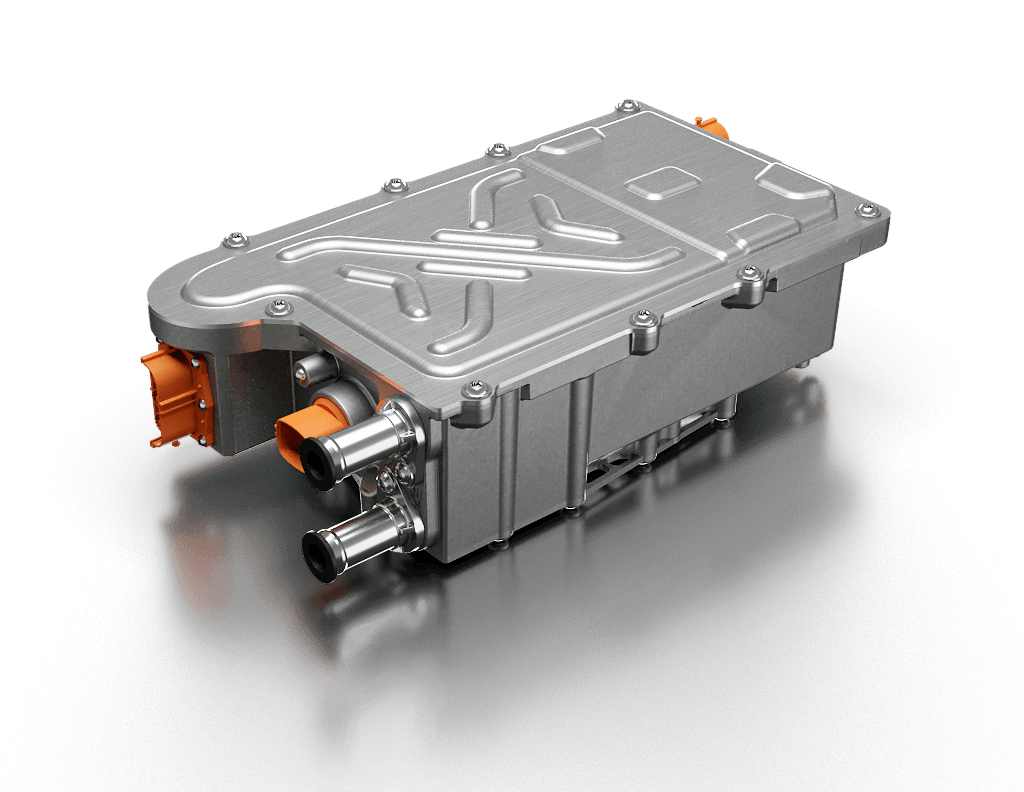

What is a High-Speed Inverter?

Our highly integrated high-speed inverters are specifically designed for operating turbo compressors in modern fuel cell and combustion engine vehicles. They control extremely compact high-speed compressors that efficiently and reliably deliver the required airflow at six-figure speeds.

Thanks to their powerful hardware architecture and precise control algorithms, the inverters ensure optimal interaction between the compressor and the fuel cell system or engine – even in minimal installation space. The perfect solution for maximum efficiency, dynamics, and reliability in mobile applications.

Features

- Modern inverter architecture: from classic B6 bridges to sophisticated multilevel converters for maximum efficiency.

- Wide voltage range: use of silicon or silicon carbide semiconductors (Si/SiC) for systems up to 800 V.

- Motor-optimized control: precisely tuned inverter to motor type, application, and operating conditions.

- Flexible system design: diverse control concepts for different application requirements – from the compressor to the drive unit.

- Comprehensive sensor technology and monitoring: monitoring of speed, sensorless rotor position detection, current, voltage, and temperature.

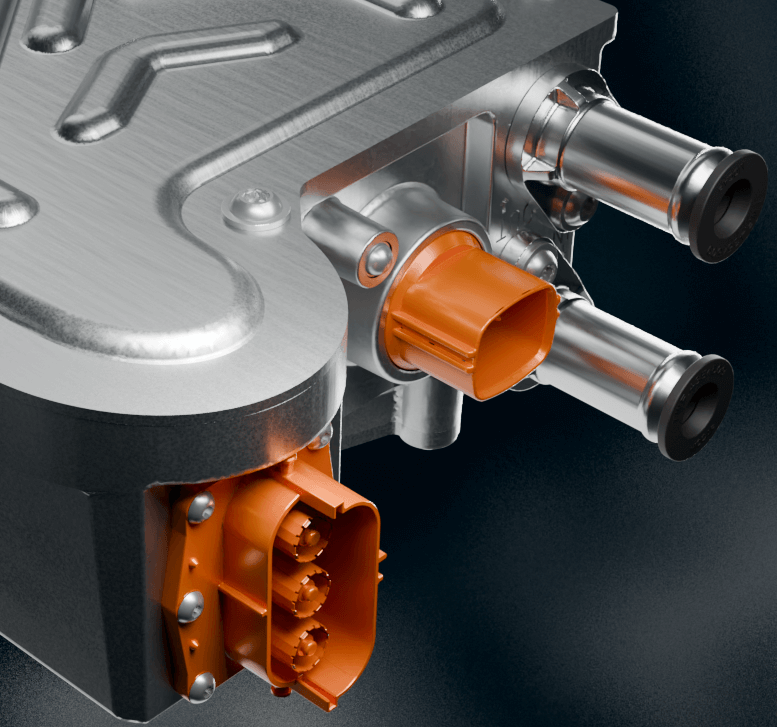

- Advanced safety functions: integrated protection through HV interlock, active discharge, short-circuit and overvoltage protection, and temperature monitoring.

- Development according to safety standards: requirements-based according to functional safety (ASIL level) and industry standards.

Applications

- Intake air compression in fuel cells

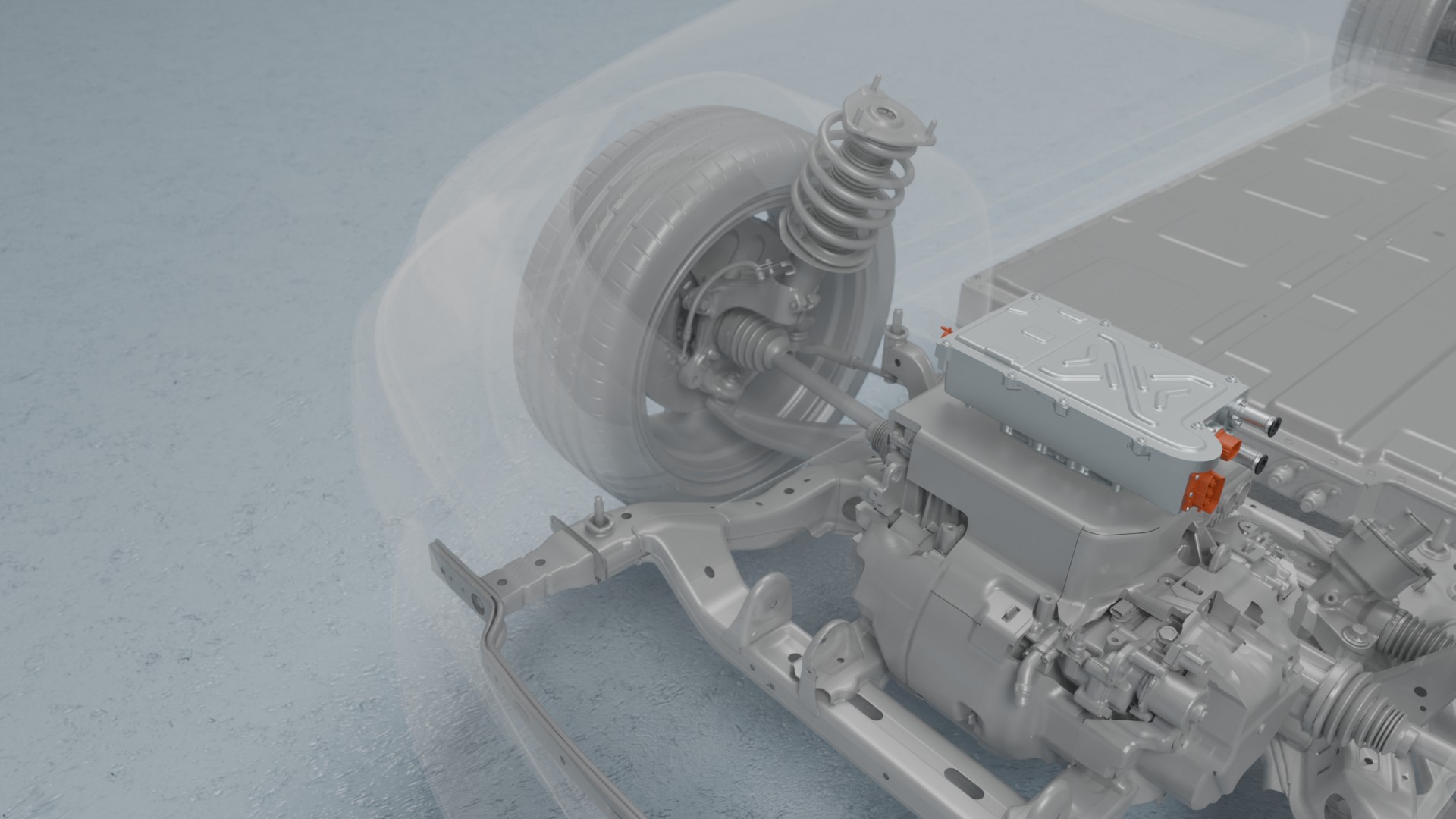

- Electric turbochargers for combustion engines

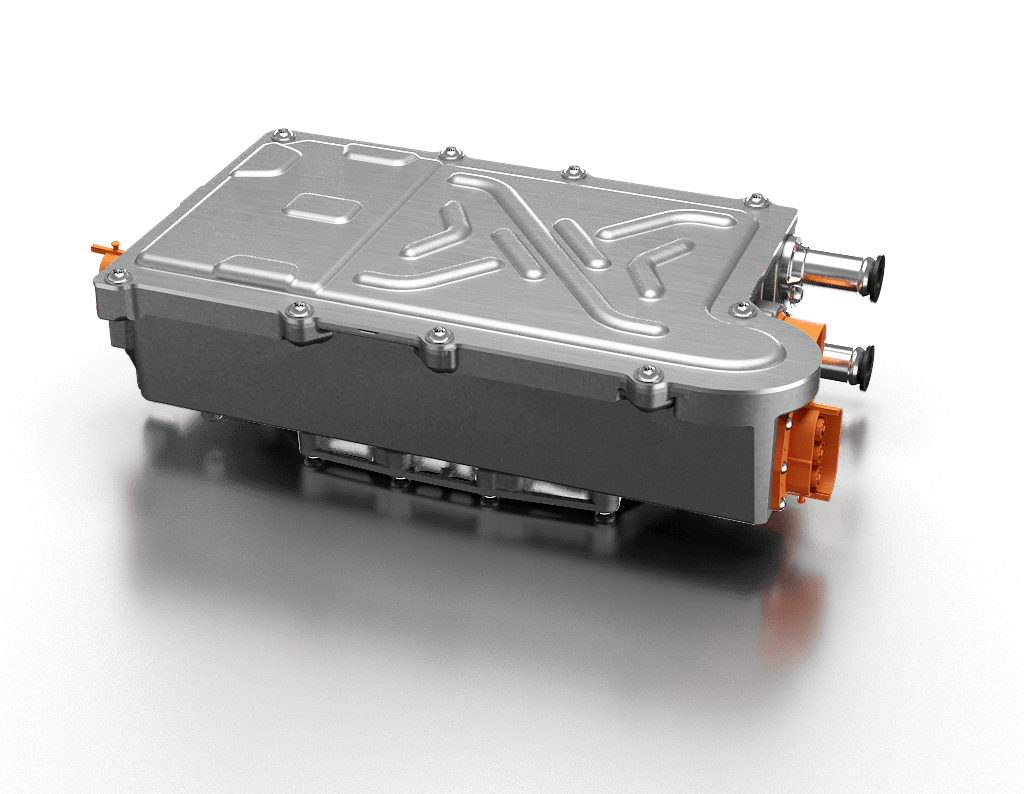

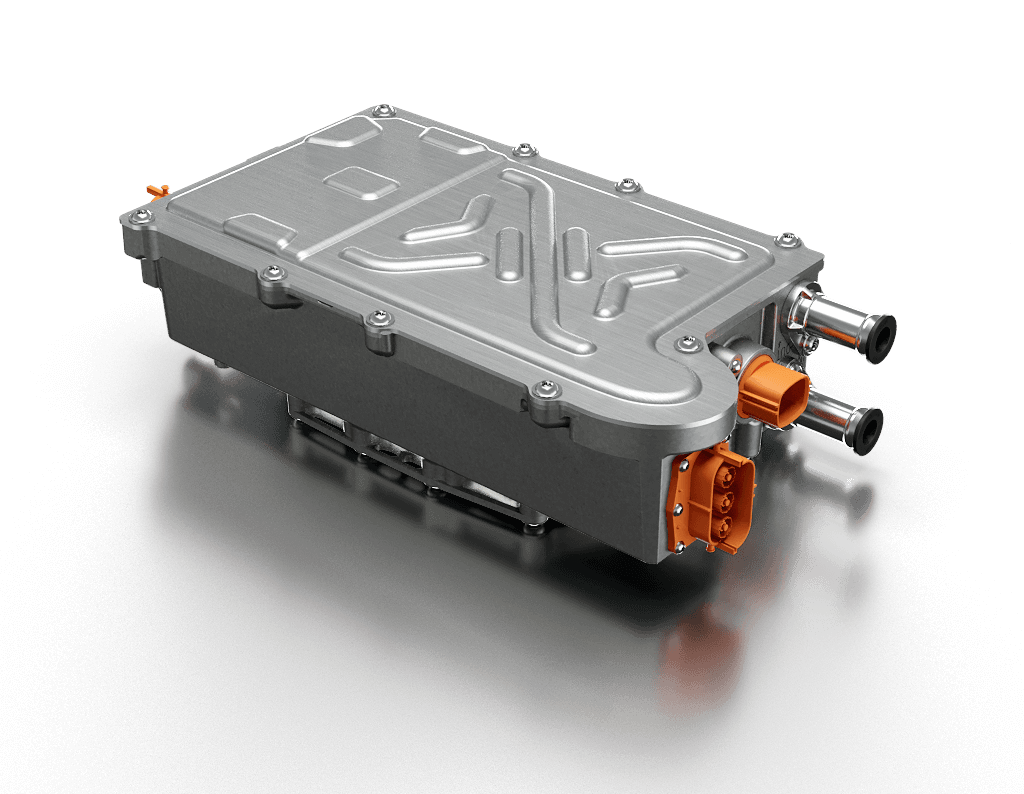

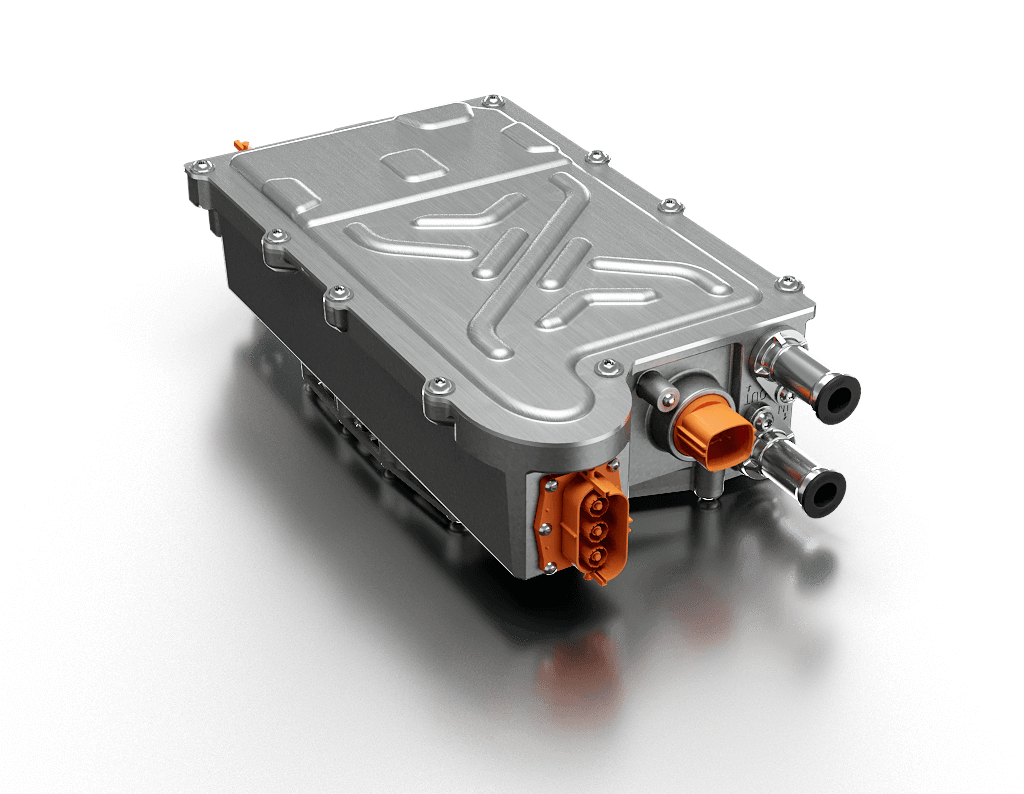

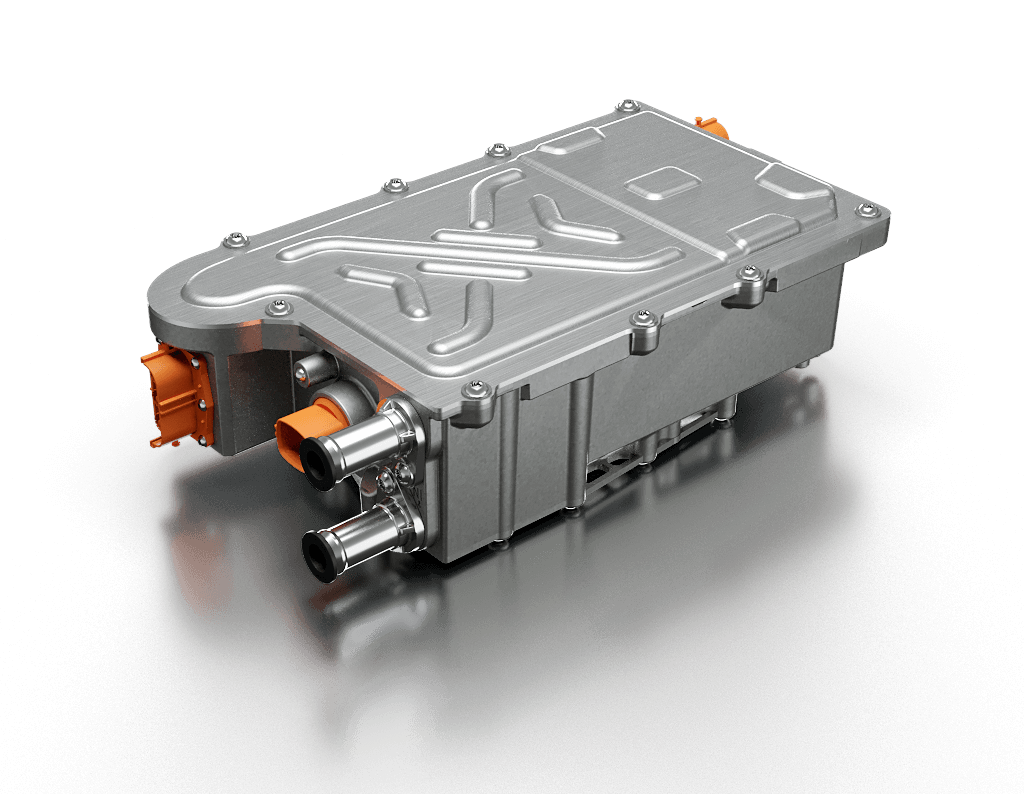

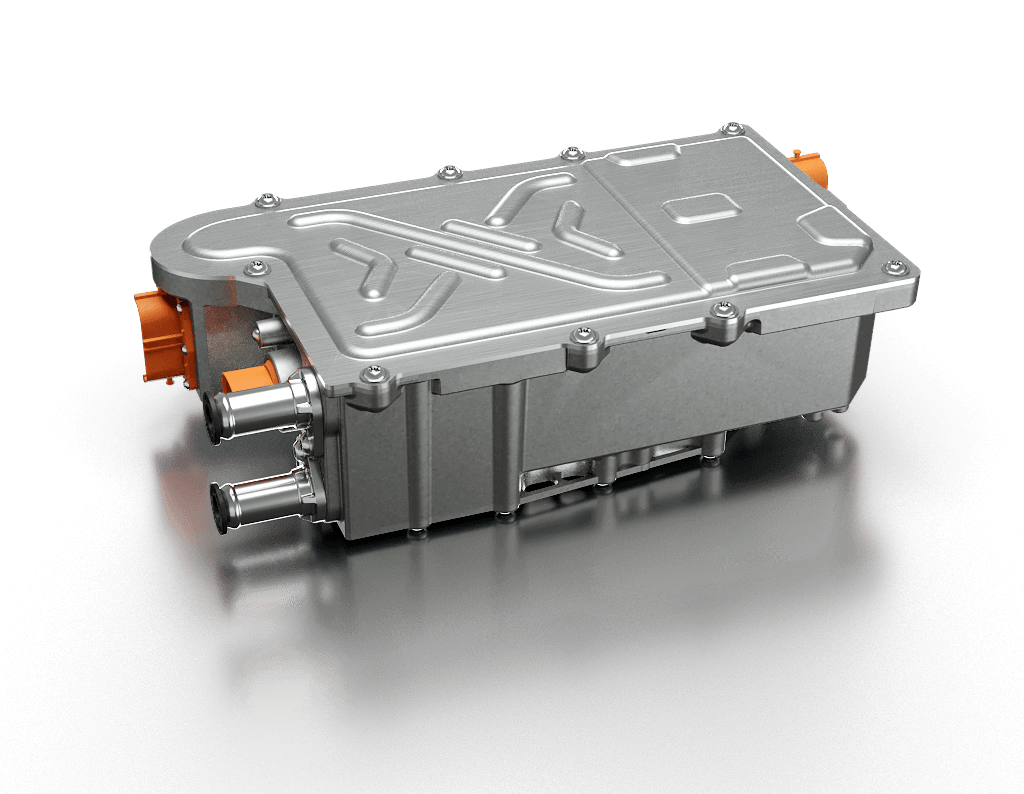

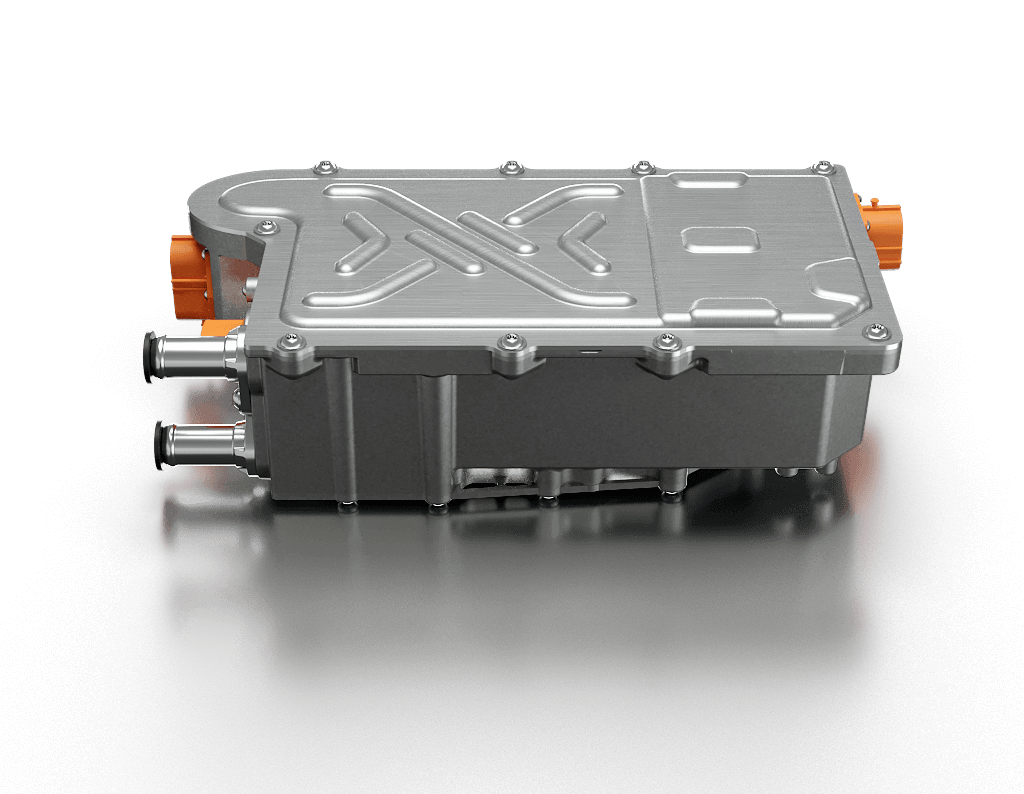

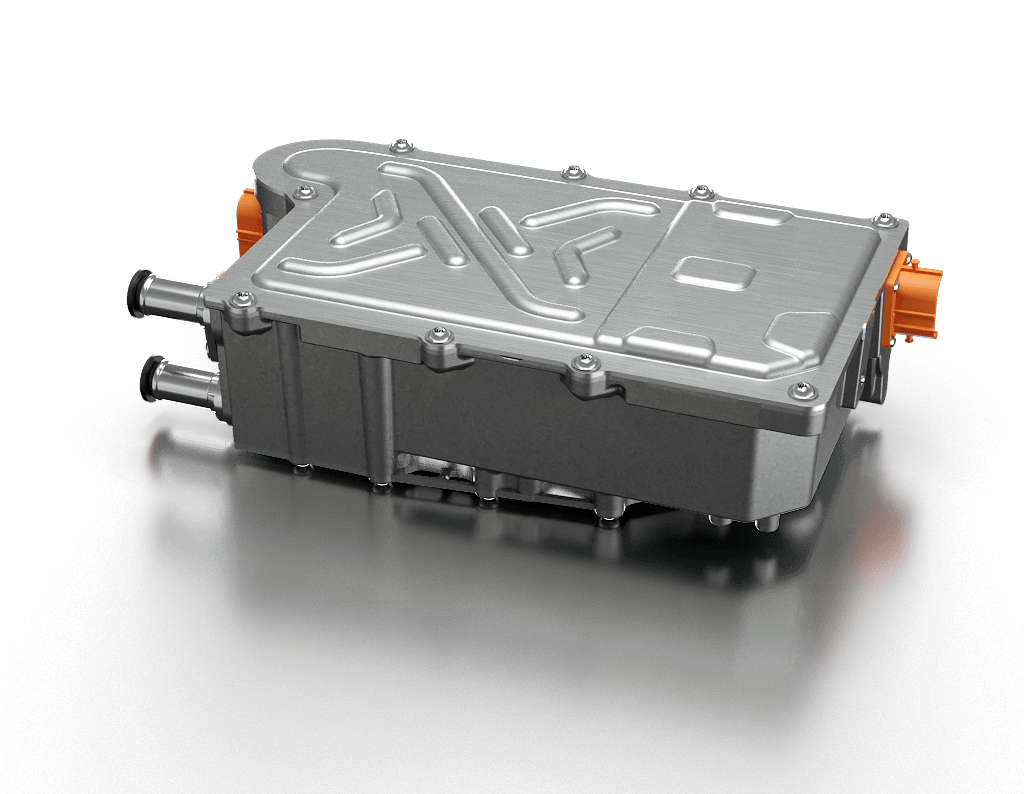

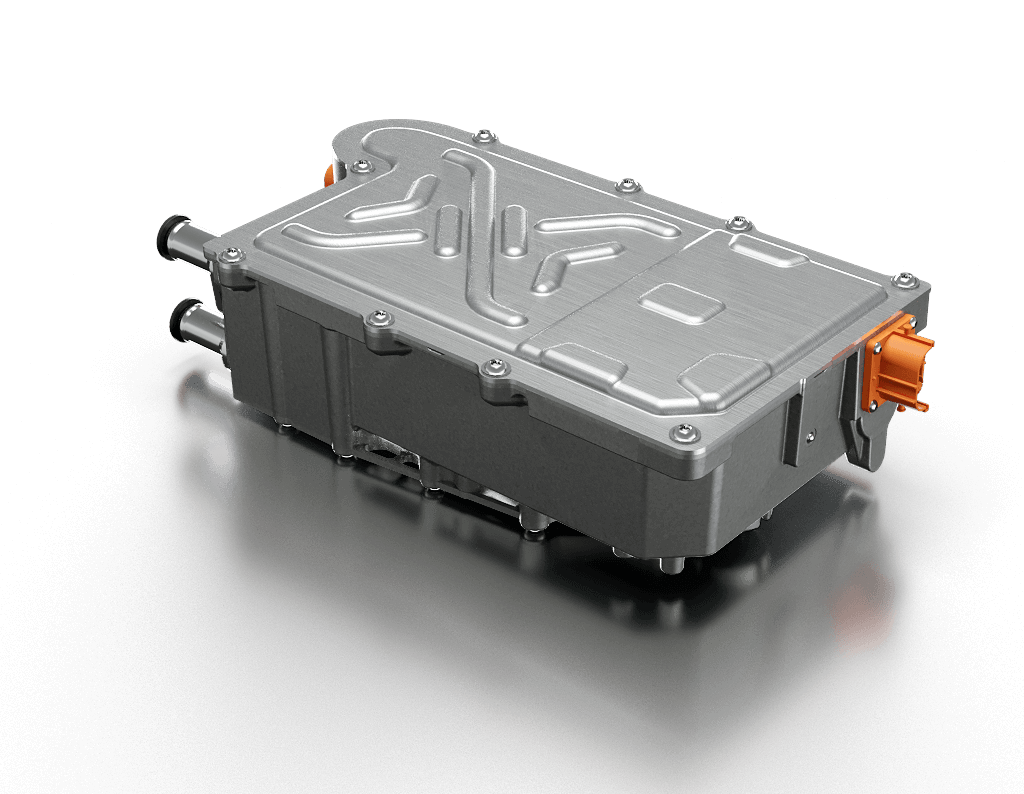

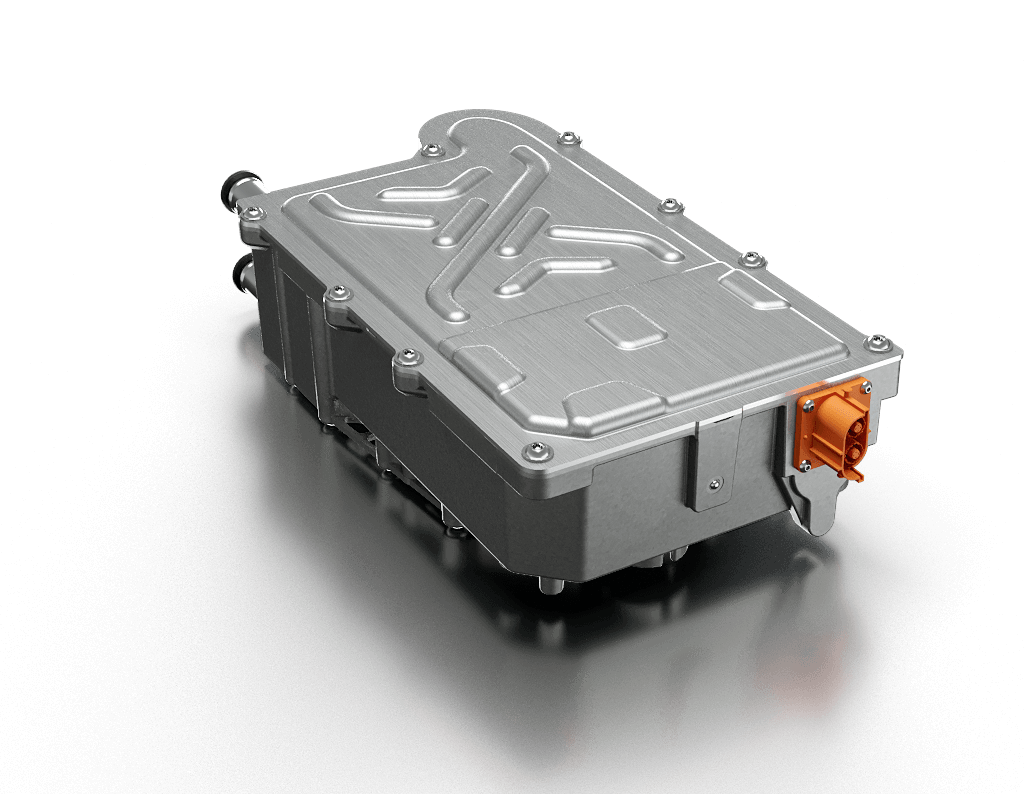

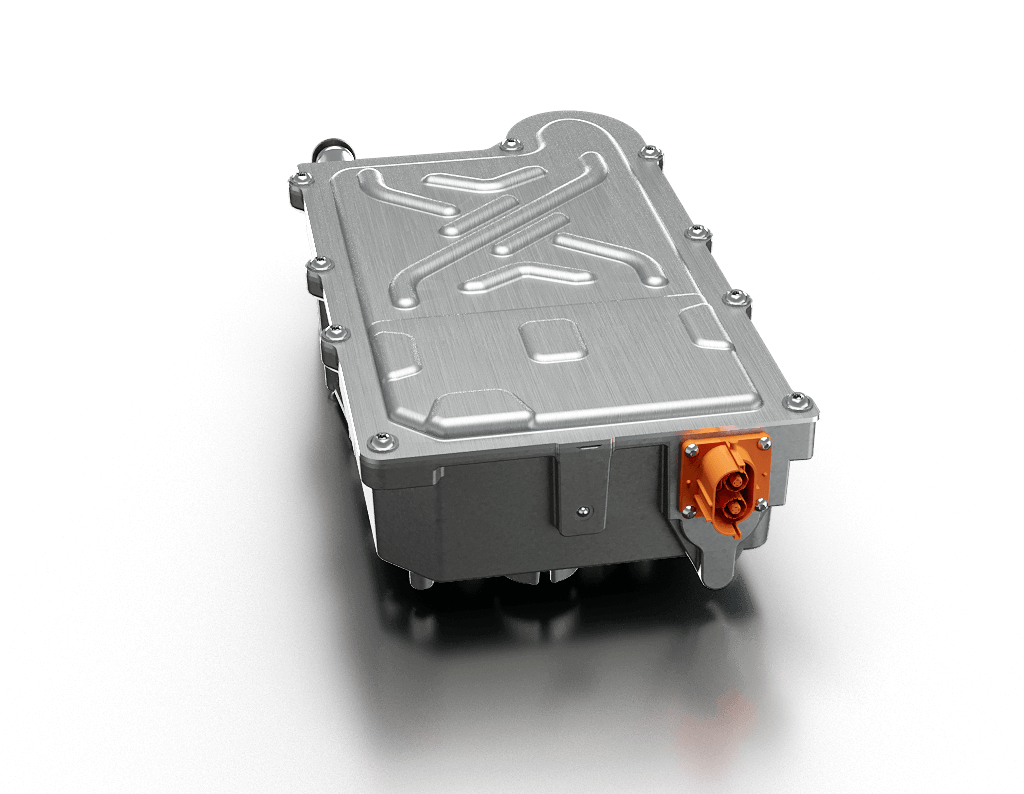

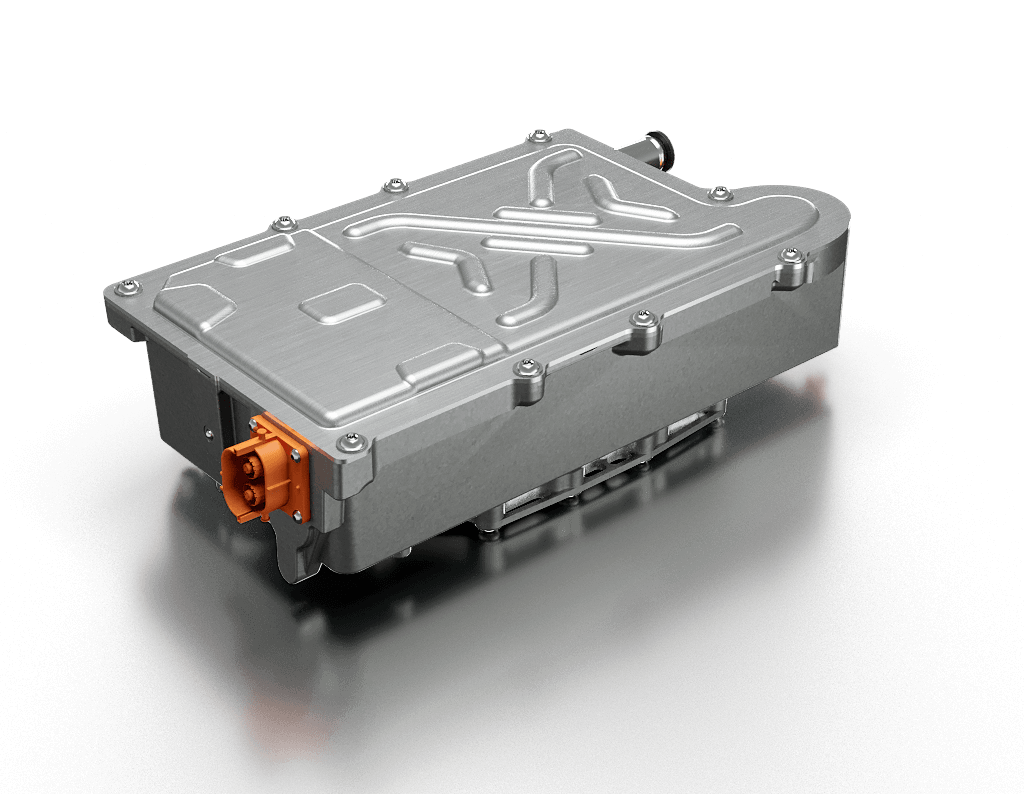

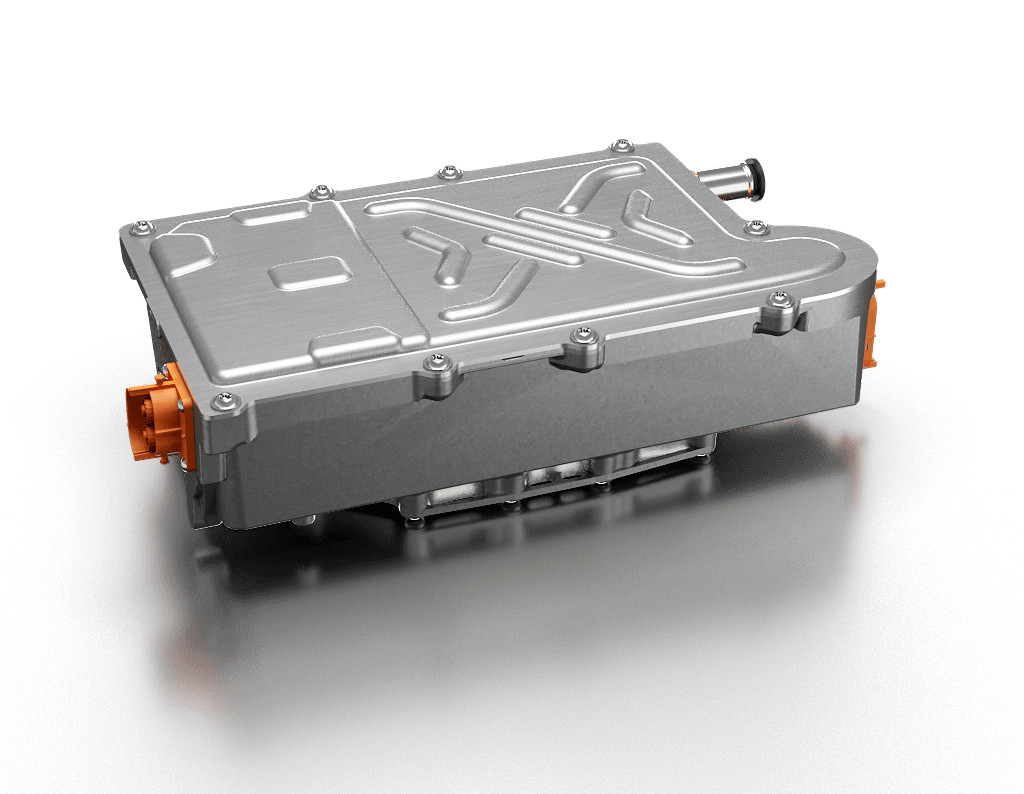

The High-Speed Inverter in 3D-View

Please click on the image to activate the 360˚ view.

Specifications

- Technology: Silicon carbide SiC (B6 bridge)

- Control: PWM up to 70 kHz for speeds up to 160,000 rpm

- Speed request: 0 to nmax in <1 s

- Voltage: 48 V to 800 V

- Power: up to 70 kW

- Safety: active discharge, HV interlock, iternal measurement technology, watchdog

- Measurement technology: speed, rotor position (sensorless), current, voltage, temperature

- Communication: ethernet, CAN, custom IOs

- Environmental conditions: temperature range -40 to +120 °C

Application Areas

- Pumps

- Compressors

- Turbocompressors

Advantages

Optimized for high-speed compressors: With speeds up to 160,000 rpm, these inverters are perfectly suited for controlling compressors with extremely high air output.

Maximum energy efficiency: Application-specific control methods such as sinusoidal commutation and multilevel architecture with DC link voltage control guarantee optimal efficiency.

For air bearing technology: The inverter enables the necessary high starting current for rapid air film formation and subsequently supports stable, reliable operation.

Why choose this product?

Our inverter for high-speed compressors impresses not only with its top technical performance, but also with its efficient development approach:

- Fast implementation: initial prototypes can be realized in just a few weeks – for a quick project start.

- Early system testing possible: our functional prototypes enable realistic testing under operational conditions – ideal for rapid validation.

- Minimized technical risk: the modular power electronics system provides you with proven, adaptable components.

- Transparent development: a clearly structured, traceable development process creates trust and predictability.

- In-depth expertise & protected IP: many years of experience in the field of high-speed inverters ensure sustainable competitive advantages.

Why Silver Atena?

Silver Atena combines many years of experience in power electronics with in-depth expertise in hydrogen, fuel cell, and high-speed technology.

Our high-speed inverters are not just highly integrated, cutting-edge products, but part of a comprehensive development and delivery strategy that secures sustainable competitive advantages for our customers.